Oil Filter Cleaner

December 2007

Prompt

Develop a product that has a positive impact on the environment.

The Team

I was one of two team leads elected to lead our team of 18 mechanical engineering students taking a senior-level product design course.

Success

Our final presentation was ranked first out of seven teams by the audience of professors, students and industry experts.

The Problem

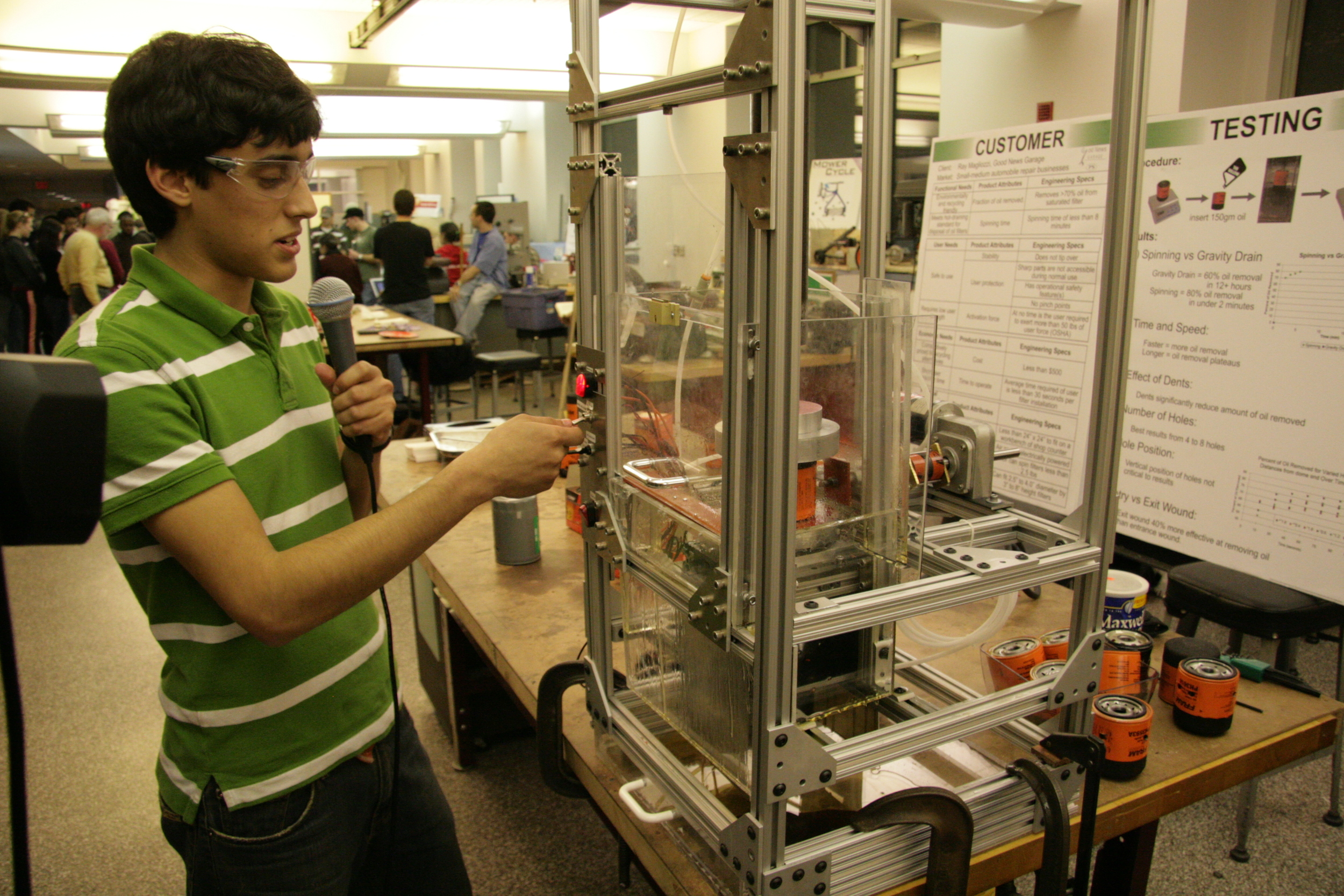

We created a machine to help solve the problem of water pollution caused by the disposal of used oil filters that haven't been entirely drained. One filter can yield 8oz. of oil, which is enough to pollute 62,000 gallons of water.

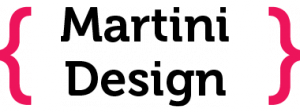

Status Quo

Most car repair shops use gravity drain systems. We did testing and found that gravity draining takes 24 hours and only drains 50% of the oil in a filter. Our machine could drain 80% of the oil within 2 minutes.

Process

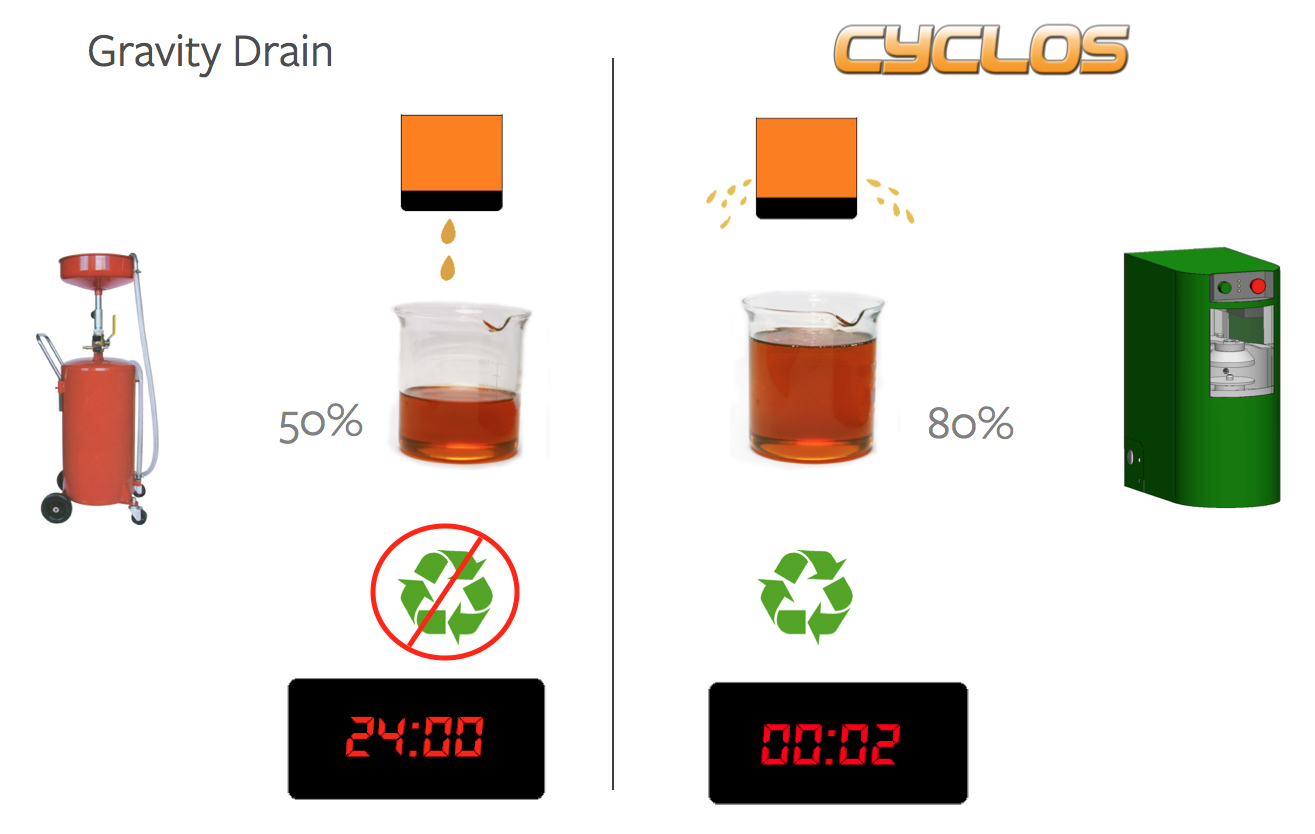

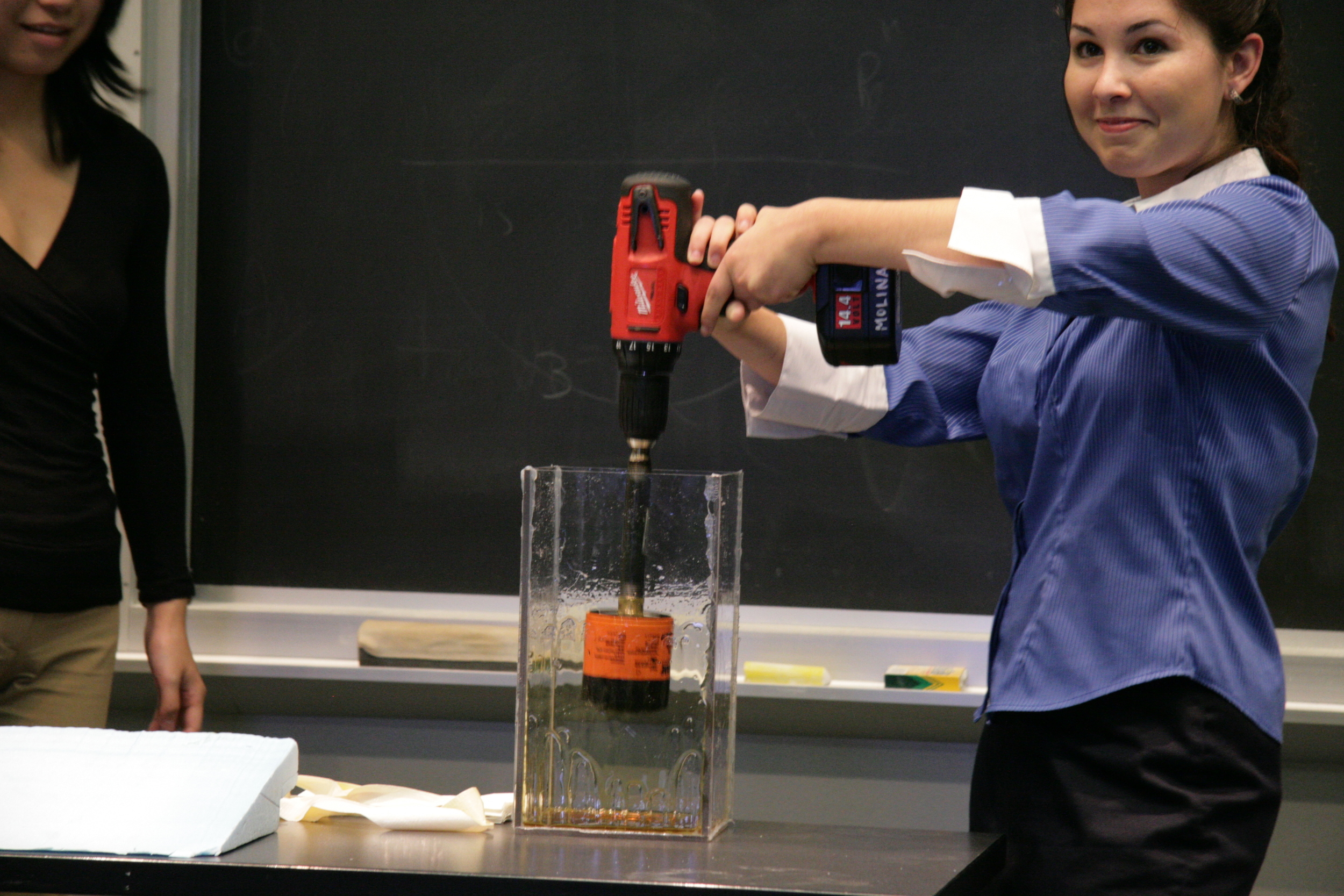

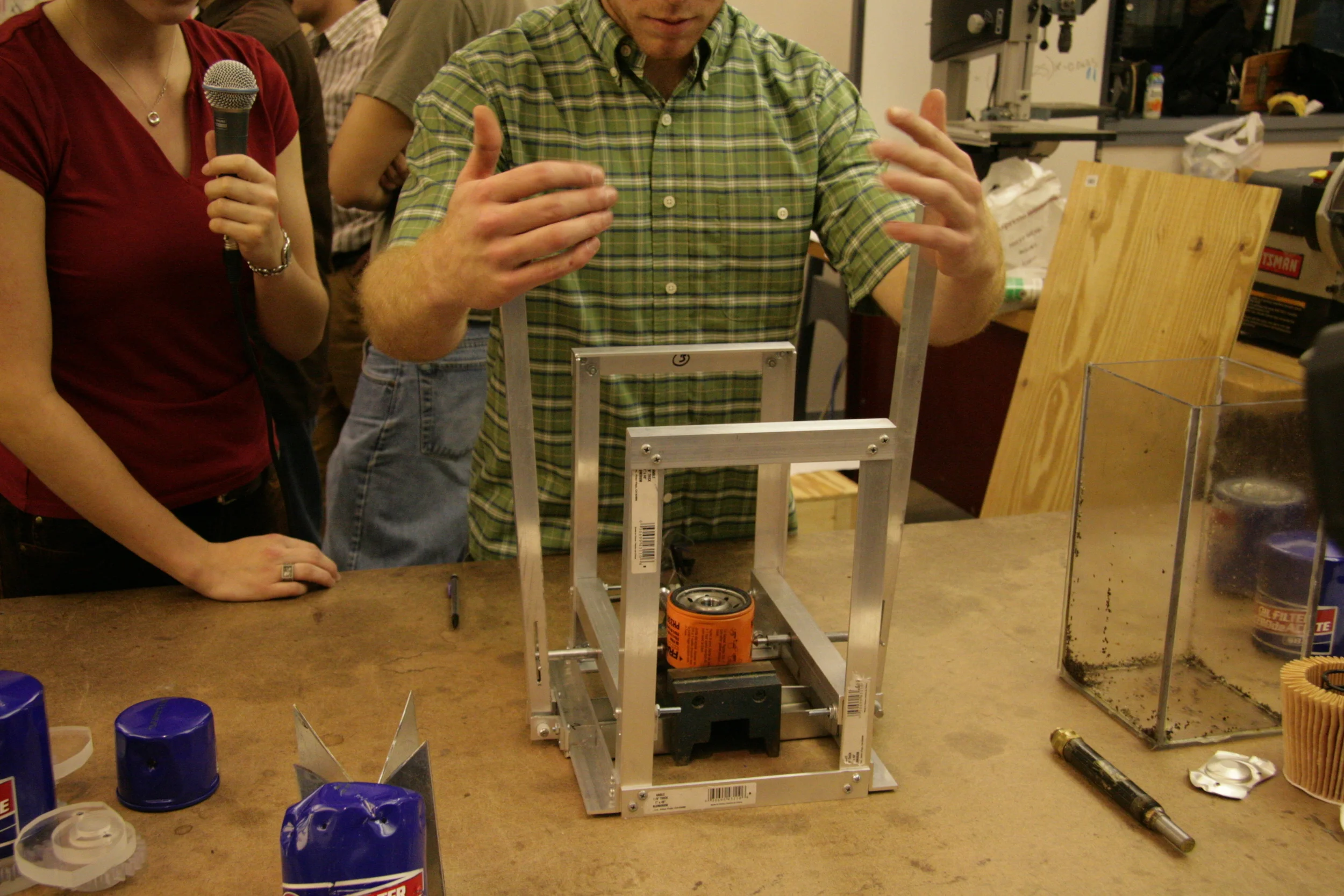

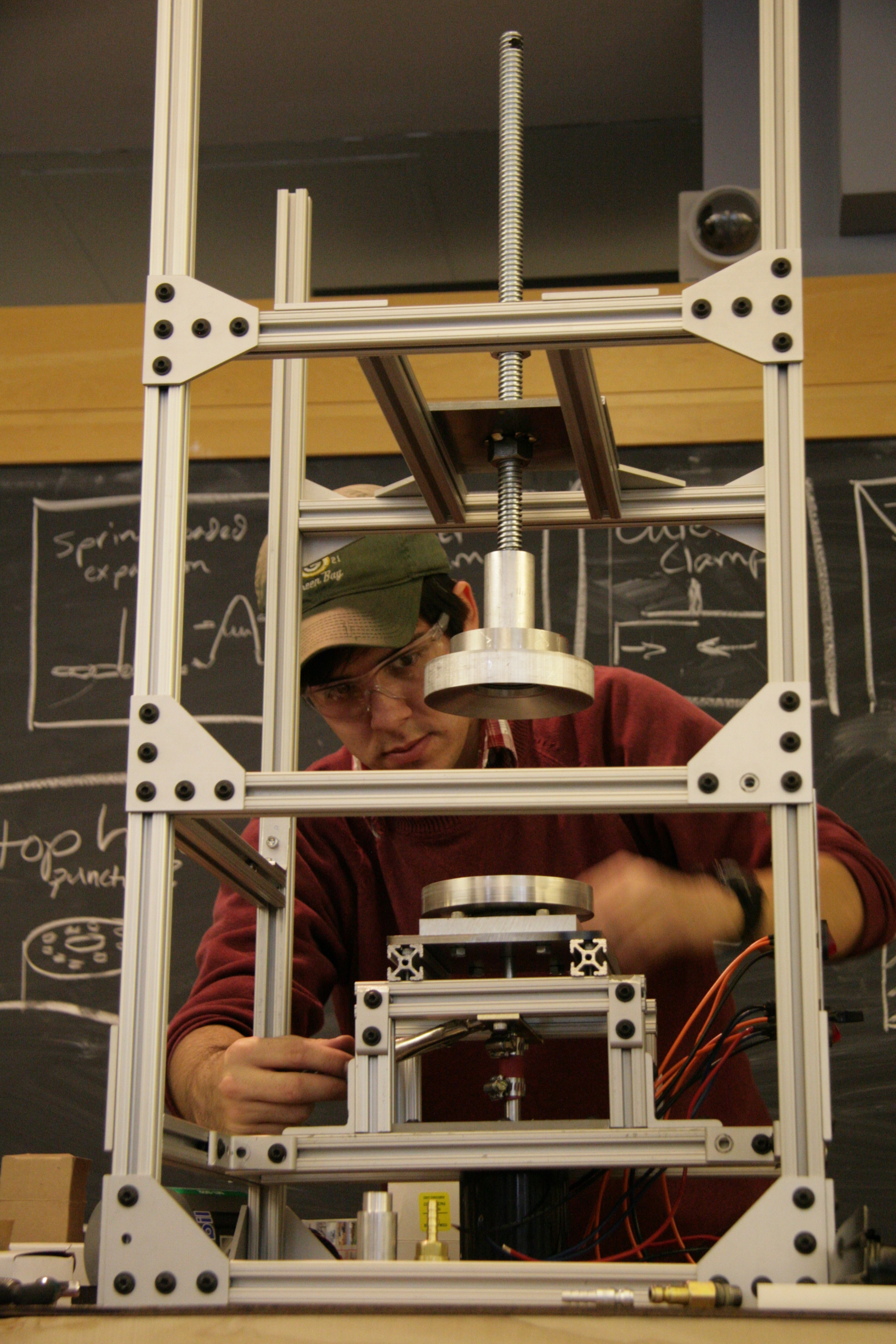

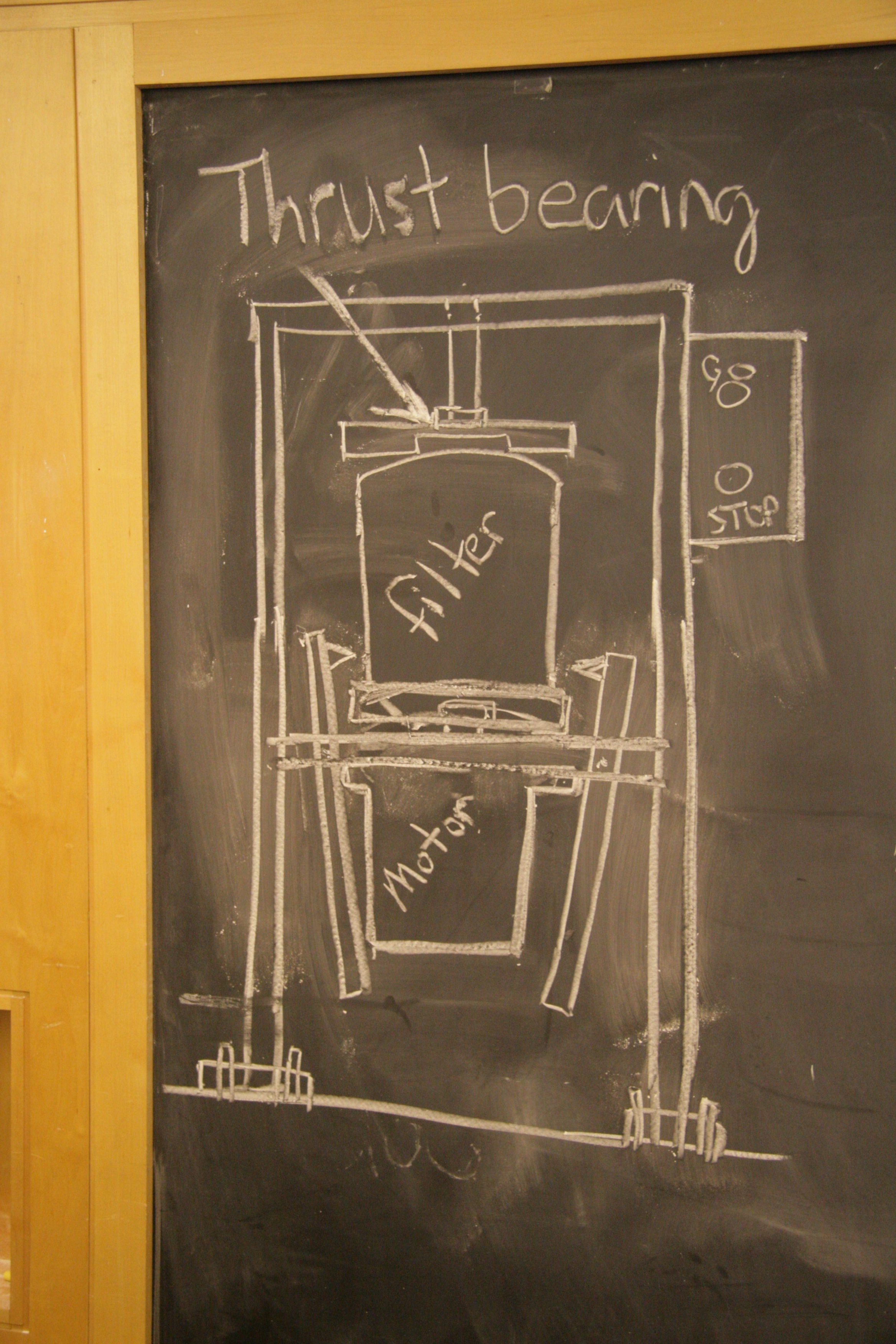

During the three-month class, the team went through multiple rounds of brainstorming, mock-ups and testing before deciding on the final design. Prototyping helped answer questions like:

- Does spinning effectively drain oil from the filters?

- What's the best mechanism for gripping any size of filter?

- What's the best way to make holes in the filter?

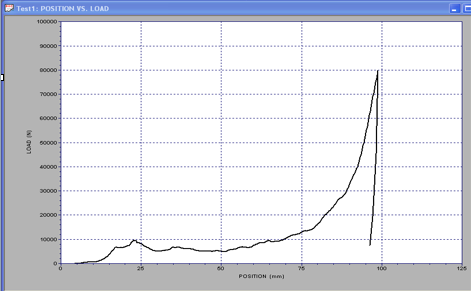

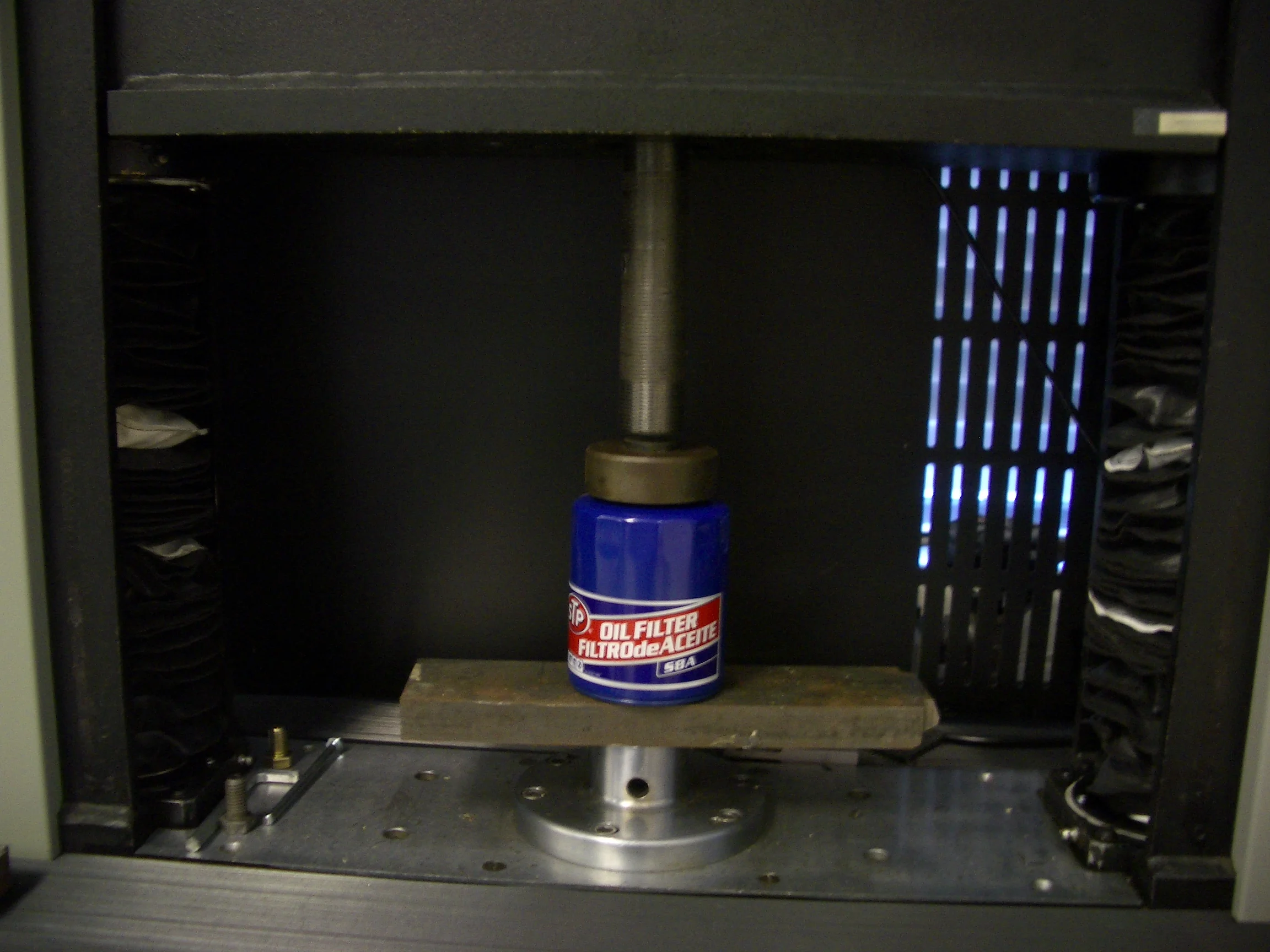

We considered crushing the can as well as spinning it. Testing showed that it took too much force, which would have added a lot of cost, and users did not find value in crushing the filters, as industrial crushers could do a much better job.

Target User

The team's "customer" consultant for this project was Ray Magliozzi of Car Talk fame at the Good News Garage. Thanks to him for his input and support. Ray represented our target user, the owner of a mechanic at an independent car repair shop.

Product Features

Our final design was styled for a nicer look, and had a number of features for safety and integrating into a machine shop.